#Flex Connector HVAC

Text

DUCT CONNECTOR

ALL SIZES

(75ft ,100ft , 150ft)

Material: Often constructed from galvanized steel or aluminum, ensuring durability and resistance to corrosion.

Flexibility: Designed to allow for flexibility and movement, accommodating thermal expansion and contraction within the HVAC system.

Sealing: Includes integrated sealing mechanisms such as gaskets or flanges to ensure airtight connections, preventing leakage of air and energy loss.

Ease of Installation: Engineered for straightforward installation, often featuring quick-connect mechanisms or screws for securing to the ductwork.

Variety: Available in various types such as straight connectors, flex connectors (which provide additional flexibility), and T-connectors (allowing branching of ducts).

Application: Used in both residential and commercial HVAC systems to join duct sections, ensuring efficient airflow and maintaining indoor air quality.

#alramiz#hvac#machines#wholesale#rewinding materials#thermostat#heater & element#are#tools & safety#acsparta#al#ramiz#DuctConnector#HVAC#Ventilation#Ductwork#AirFlow#HVACSystems#DuctInstallation#HVACTechnology#AirDistribution#DuctFittings#BuildingHVAC#ClimateControl#HVACEngineering#DuctConnection#HVACEquipment

1 note

·

View note

Text

Dear Customers,

We have special Promotion Sales for you if you do EV Chargers and HVAC installation.

TECK90 Cable

6/3c $14.45/m

8/2c $6.85/m

8/3c $8.85m

10/2c $4.85/m

10/3c $5.95/m

Energy management Device:

No need upgrade your load center any more for EV Charger, A/C and Dryers.

100A $680.00

200A $690.00

Outdoor Receptacle for EV Charger

HJ14-1450 240v 50A $38.85

Flex. A/C Whip:

NMW-756 $17.85

A/C Disconnect

NF Pull out disconnect 60A $16.85ea

Meanwhile we have more Flex. conduits and water proof Connector fittings on SALES.

Prices are valid till the end of May, 2024.

First come , First serve as Limited inventory lasts each store.

Looking forward to seeing you!

Sincerely

Ameleco Sales Team

AMELECO

One Stop Electrical Supplier - Since 2010

Vancouver Breakers Depot. LED Warehouse Sales

Burnaby office:

4012 Myrtle street, Burnaby, BC. V5C 4G2

Tel: (604) 570-0867

Fax: (604) 570-0807

Email: [email protected]

Website: http://www.ameleco.com

Richmond branch:

Unit 3~4, 12331 Bridgeport road, Richmond, BC. V6V 1J4

Tel: (778) 296-2570

Port Coquitlam branch:

Unit 420, 1952 Kingsway Ave, Port Coquitlam, BC. V3C 6C2

Tel: (778) 285-3999

Mon.~Fri.: 7:00am~5:00pm

Sat.: 8:00am~2:00pm

1 note

·

View note

Text

Metal Flex Bellows And Copper Alloy Bellows: Versatile Solutions For Various Industries

In the ever-evolving landscape of engineering and manufacturing, the demand for flexible and robust components continues to rise. This demand has paved the way for the emergence of two remarkable products: Metal Flex Bellows and Copper Alloy Bellows. These innovative bellows offer unparalleled versatility in a variety of applications. Let's explore further to understand their definitions, characteristics, and widespread use across industries.

Metal Flex Bellows, also known as metallic expansion joints, are meticulously engineered components designed to absorb thermal expansion, vibration, and misalignment in piping systems. Constructed from premium-grade metals such as stainless steel, inconel, or hastelloy, these bellows consist of a series of convoluted metal layers. The unique interlocked design enables axial, lateral, and angular movement, while maintaining the integrity of the system.

The Metal Flex Bellows offer exceptional benefits across industries. In HVAC systems, they provide flexibility to compensate for temperature-induced expansion and contraction, ensuring the integrity of air conditioning ducts. In automotive applications, they absorb vibration and reduce stress, contributing to a longer lifespan for exhaust systems. Moreover, in aerospace and defense manufacturing, these bellows solutions alleviate thermal and mechanical stresses, avoiding structural failure and ensuring good performance.

In parallel, Copper Alloy Bellows represent another remarkable innovation. Composed of copper, a malleable and corrosion-resistant material, these bellows possess good electrical and thermal conductivity. Their inherent ductility enables them to accommodate various mechanical movements and environmental conditions. Copper Alloy Bellows find extensive use in industries necessitating hermetic seals, such as electrical connectors, switches, and sensors.

Due to their superior characteristics, Copper Alloy Bellows enjoy diverse applications. In electric vehicles, they serve as critical components for battery systems, protecting against thermal expansion and vibrations. In the telecommunications sector, they enable efficient fiber optic connections, shielding against temperature fluctuations and mechanical stress. Additionally, in healthcare equipment, Copper Alloy Bellows are embedded within medical devices to ensure accurate pressure measurements and enable safe, airtight connections.

The adaptability and reliability of Metal Flex Bellows and Copper Alloy Bellows have made them important across industries. Their usage continues to expand as the demand for precision, durability, and performance intensifies. The key features of these bellows solutions, such as high-pressure resistance, flexible movement, and resistance to hard temperatures, have cemented their position as essential components in critical applications.These two innovative products, Metal Flex Bellows and Copper Alloy Bellows, offer good flexibility and durability in various industries. From aerospace to automotive, these bellows have proven to be indispensable in critical applications where precise movement, durability, and protection against extreme conditions are paramount.

In conclusion, Metal Flex Bellows and Copper Alloy Bellows epitomize advanced solutions in the engineering and manufacturing realm. Both products offer advanced features, ensuring their outstanding performance and adaptability across various sectors. As the demand for flexible, durable, and reliable components surges, these bellows solutions play a pivotal role in diverse applications, protecting systems from thermal expansion, vibrations, misalignments, and more. Their contributions to industries such as HVAC, automotive, aerospace, telecommunications, and healthcare cannot be overstated, making them important tools for modern engineering needs.

0 notes

Text

Metallic Flexible Hose

Here are some key characteristics and uses of metallic flexible hoses:

Material: Metallic flexible hoses are typically constructed from various metals or metal alloys, such as stainless steel, bronze, or other corrosion-resistant materials. The choice of material depends on the specific application and the fluid or gas being transported.

Corrosion Resistance: Many metallic hoses are resistant to corrosion and can handle a wide range of chemicals and aggressive media, making them suitable for use in chemical processing, petrochemical, and offshore industries.

Temperature and Pressure Range: Metallic flexible hoses are designed to operate at a wide range of temperatures and pressures. They can handle extreme temperatures, from cryogenic temperatures to high-temperature applications. The pressure rating depends on the hose’s construction and material.

Flexibility: These hoses are highly flexible, allowing them to bend and flex without compromising their structural integrity. This flexibility makes them suitable for applications where movement or vibration is present, such as in industrial machinery, exhaust systems, or pipelines.

Absorption of Vibrations: Metallic flexible hoses can absorb and dampen vibrations and shocks, which can help protect equipment and extend the lifespan of components in various industrial settings.

Compensation for Thermal Expansion/Contraction: In piping systems subjected to temperature changes, metallic hoses can accommodate thermal expansion and contraction, reducing the stress on the system and preventing damage.

Connectors and Fittings: Metallic flexible hoses are typically equipped with specialized connectors and fittings at each end to facilitate easy installation and connection to other components in a system.

Applications: Metallic flexible hoses find use in a wide range of industries and applications, including:

HVAC (Heating, Ventilation, and Air Conditioning) systems

Automotive and aerospace industries

Steam and hot water distribution

Chemical processing

Oil and gas refining

Cryogenic applications

Food processing and pharmaceuticals

Power generation (e.g., exhaust systems)

Shipbuilding and offshore drilling

These hoses are available in various lengths and diameters to suit specific requirements. When selecting a metallic flexible hose, it is crucial to consider factors like temperature, pressure, compatibility with the conveyed media, and environmental conditions to ensure safe and efficient operation. Proper maintenance and inspection are also essential to ensure the integrity and reliability of these hoses over time.

0 notes

Text

The Advantages and Disadvantages of Flexible Ducting

Flexible ducting is a common type of HVAC system used in both homes and businesses. It is made up of a round wire coil that is encased in a bendable polymer skin and a layer of fiberglass insulation. It is also typically covered by a thin polyethylene or foil jacket to protect it from moisture and damage.

It is less expensive to install than sheet metal ductwork. When you consider materials, installation and labor costs, the cost of a standard metal duct is almost twice as much as that of flexible ductwork that comes pre-insulated. All of the above, you need to choose the right flexible ducting for your requirements.

Unlike sheet metal, which is rigid and needs to be cut to size by a professional, flexible ducting can be easily bent to fit the framing of a building. This makes it ideal for areas such as attics where roof trusses, floor joists, and other components are hard to reach.

The most important factor to consider when choosing a duct material is airflow. If air isn't flowing properly, your equipment won't run efficiently, and the indoor air quality will suffer.

This is because flexible ductwork can be too thick, which increases the amount of resistance to airflow. Additionally, the material can crumple under its own weight, which reduces the flow of air.

It can be difficult to get the ducts in place correctly. This is because it is very difficult to access attic spaces and walk around ceilings and joists to set up the ducts and the right elbows and bends. This can be a very time consuming process.

You need to do everything possible to ensure that flex duct is installed correctly. This is because if it is not installed correctly, it will not work as well and will be more costly to fix in the future.

If you are going to have a contractor install flexible ductwork, they should use top rated duct mastic at all connectors and tie wraps at all elbows and bends. They should also have a plan for all ducts to run through designated chases and trusses to ensure maximum airflow.

Another thing to consider is the length of the ducts. If they are too long, it will be impossible to bend them around roof rafter components or floor joists in the attic. This can severely limit airflow and increase the amount of energy you'll have to spend on your heating and cooling.

Having strong airflow is crucial for any HVAC system. It helps your unit to run more efficiently and saves you money on energy bills. To achieve this, your ductwork must be routed through ceiling plenums and ducted through the home or business to each room where you want it to deliver air.

It is also crucial to make sure that all ducts are stretched tight between fittings and don't contain sharp bends that can reduce airflow and increase the length of the equivalent duct by several multiples.

Having all of this in mind can help you to decide whether or not you should use flexible ducts for your next ductwork project. It is not a decision to be taken lightly.

0 notes

Photo

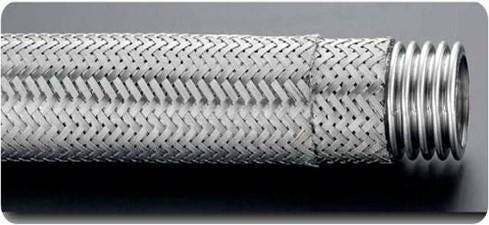

Welded stainless steel metal hose The applications that we support range from metal hose requirements for furnace cooling applications, oxygen services, HVAC offsets, hot asphalt jumper hoses, flanged assemblies for flex connectors, chemical processing, petroleum based applications, natural gas, vibration absorption hoses, earthquake hoses and much more.

0 notes

Text

Eastman Gas Connector – 5/8 in. OD 1/2 in. MIP x MIP

The Steel-Flex® gas connector by Eastman® is made of stainless steel with a yellow epoxy coating and a 5/8-inch OD (1/2-inch NOM.). The deep corrugations of the connector provide structural support against crushing, kinking and cracking. The epoxy coating is designed to withstand long exposure to household chemicals and harsh environments. This is a highly durable connector with zinc-plated steel 1/2-inch MIP x 1/2-inch MIP fittings. CSA certified in both US and Canada.This connector can be used as a gas supply line in HVAC applications, water heaters, ranges, and other appliances. Works with propane or natural gas.

Technical Specifications

Construction: Yellow epoxy coated stainless steel 304 (ASTM 240)

Connection: Zinc-plated steel S45C fittings 1/2 in. MIP x 1/2 in. MIP

Connector OD: 5/8 in. OD (1/2 in. NOM)

Natural Gas Capacity: up to 106,000 BTUh *Multiply by 1.6 for LP Gas

0 notes

Text

PCB Types Introduction

There are several overall types of PCB boards each with their own particular manufacturing specifications, material types and usages: Single-layer PCBs, Double-layer PCBs, Multi-layer PCBs, Rigid PCBs, Flexible PCBs, Rigid-Flex PCBs, High-frequency PCBs, Aluminum-backed PCBs.

Single-layer PCBs

A single-layer or single-sided PCB is one that is made out of a single layer of base material or substrate. One side of the base material is coated with a thin layer of metal. Copper is the most common coating due to how well it functions as an electrical conductor. Once the copper base plating is applied, a protective solder mask is usually applied, followed by the last silk-screen to mark out all of the elements on the board.

Since single-layer/single-sided PCBs only have their various circuits and components soldered onto one side, they are easy to design and manufacture. This popularity means that they can be purchased at a low-cost, especially for high-volume orders. The low-cost, high volume model means they are commonly used for a variety of applications, including calculators, cameras, radio and stereo equipment, solid state drives, printers and power supplies.

Double-layer PCBs

Double-layer or double-sided PCBs have a base material with a thin layer of conductive metal, like copper, applied to both sides of the board. Holes drilled through the board allow circuits on one side of the board to connect to circuits on the other.

The circuits and components of a double-layer PCB board are usually connected in one of two ways: either utilizing a through-hole or with the use of a surface-mount. A through-hole connection means that small wires, known as leads, are fed through the holes, with each end of the leads then soldered to the right component.

Surface mount PCBs don't utilize wires as connectors. Instead, many small leads are soldered directly to the board, meaning that the board itself is used as a wiring surface for the different components. This allows circuits to be completed using less space, freeing up space to allow the board to complete more functions, usually at higher speeds and a lighter weight than a through-hole board would allow.

Double-sided PCBs are typically used in applications which require an intermediate level of circuit complexity, such as Industrial controls, Power supplies, Instrumentation, HVAC systems, LED lighting, Automotive dashboards, Amplifiers and Vending machines.

Multi-layer PCBs

Multi-layer PCBs consist of a series of three or more double-layered PCBs. These boards are then secured together with a specialized glue and sandwiched between pieces of insulation to ensure that excess heat doesn't melt any of the components. Multi-layer PCBs come in a variety of sizes, going as small as four layers or as large as ten or twelve. The largest multi-layer PCB ever built was 50 layers thick.

With many layers of printed circuit boards, designers can make very thick, complex designs which are suitable for a broad range of complicated electrical tasks. Applications where multi-layer PCBs would be beneficial include File servers, Data storage, GPS technology, Satellite systems, Weather analysis and Medical equipment.

Rigid PCBs

Rigid PCBs are printed circuit boards that are made out of a solid substrate material that prevents the board from twisting. Possibly the most common example of a rigid PCB is a computer motherboard. The motherboard is a multilayer PCB designed to allocate electricity from the power supply while simultaneously allowing communication between all of the many parts of the computer, such as CPU, GPU and RAM.

Rigid PCBs make up perhaps the largest number of PCBs manufactured. These PCBs are used anywhere that there is a need for the PCB itself to be set up in one shape and remain that way for the remainder of the device's lifespan. Rigid PCBs can be anything from a simple single-layer PCB all the way up to an eight or ten-layer multi-layer PCB.

All Rigid PCBs have single-layer, double-layer or multilayer constructions, so they all share the same applications.

Flexible PCBs

Unlike rigid PCBs, which use unmoving materials such as fiberglass, flexible PCBs are made of materials that can flex and move, such as plastic. Like rigid PCBs, flexible PCBs come in single, double or multilayer formats. As they need to be printed on a flexible material, they tend to cost more for fabrication.

Still, flexible PCBs offer many advantages over rigid PCBs. The most prominent of these advantages is the fact that they are flexible. This means they can be folded over edges and wrapped around corners. Their flexibility can lead to cost and weight savings since a single flexible PCB can be used to cover areas that might take multiple rigid PCBs.

Flexible PCBs can also be used in areas that might be subject to environmental hazards. To do so, they are simply built using materials that might be waterproof, shockproof, corrosion-resistant or resistant to high-temperature oils - an option that traditional rigid PCBs may not have.

Flex-rigid PCBs

Flex-rigid PCBs combine the best of both worlds when it comes to the two most important overarching types of PCB boards. Flex-rigid boards consist of multiple layers of flexible PCBs attached to a number of rigid PCB layers.

Flex-rigid PCBs have many advantages over just using rigid or flexible PCBs for certain applications. For one, rigid-flex boards have a lower parts count than traditional rigid or flexible boards because the wiring options for both can be combined into a single board. The combination of rigid and flexible boards into a single rigid-flex board also allows for a more streamlined design, reducing the overall board size and package weight.

Flex-rigid PCBs are most often found in applications where space or weight are prime concerns, including Cell phones, Digital cameras, Pacemakers and Automobiles.

High-frequency PCBs

High-frequency PCBs refer to a general PCB design element, rather than a type of PCB construction like the previous models. High-frequency PCBs are circuit boards that are designed to transmit signals over one gigahertz.

High-frequency PCB materials often include FR4-grade glass-reinforced epoxy laminate, polyphenylene oxide (PPO) resin and Teflon. Teflon is one of the most expensive options available because of its small and stable dielectric constant, small amounts of dielectric loss and overall low water absorption.

Many aspects need to be considered when choosing high-frequency PCB board and its corresponding type of PCB connector, including dielectric constant (DK), dissipation, loss and dielectric thickness.

The most important of those is the Dk of the material in question. Materials with high probability for the change of dielectric constant often have changes in impedance, which can disrupt the harmonics that make up a digital signal and cause an overall loss of digital signal integrity — one of the things that high-frequency PCBs are designed to prevent.

Other things to consider when choosing the boards and PC connector types to use when designing a high-frequency PCB are:

• Dielectric loss (DF), which affects the quality of signal transmission. A smaller amount of dielectric loss could make a small amount of signal wastage.

• Thermal expansion. If the thermal expansion rates of the materials used to build the PCB, such as copper foil, are not the same, then materials could separate from each other due to changes in temperature.

• Water absorption. High amounts of water intake will affect the dielectric constant and dielectric loss of PCB, especially if it is used in wet environments.

• Other resistances. The materials utilized in the construction of a high-frequency PCB should be rated highly for heat resistance, impact endurance and resistance to hazardous chemicals, as necessary.

Aluminum-Backed PCBs

Aluminum-backed PCBs are designed in much the same way as their copper-backed counterparts. However, instead of the usual fiberglass used in most PCB board types, aluminum-backed PCBs make use of aluminum or copper substrate board.

The aluminum backing is lined with thermally insulating material that is designed to have a low thermal resistance, meaning less heat is transferred from the insulating material to the backing. Once the insulation is applied, a circuit layer of copper, ranging in thickness from one ounce to ten, is applied.

Aluminum-backed PCBs have many advantages over PCBs with a fiberglass backing, including:

• Low cost. Aluminum is one of the most abundant metals on Earth, making up 8.23% of the planet's weight. Aluminum is easy and inexpensive to mine, which helps to cut expenses in manufacturing process. Thus, building products with aluminum is less expensive.

• Environmentally friendly. Aluminum is non-toxic and easily recyclable. Manufacturing printed circuit boards out of aluminum is also a good way to conserve energy.

• Heat dissipation. Aluminum is one of the best materials available for dissipating heat away from crucial components of circuit boards. Instead of dispersing the heat out into the rest of the board, it transfers heat out into the open air. Aluminum PCB cools faster than an equivalent-sized copper PCB.

• Material durability. Aluminum is far more durable than materials like fiberglass or ceramic, especially for drop tests. The use of sturdier base materials helps reduce damage during manufacture, shipping and installation.

All of these advantages make Aluminum PCBs an excellent choice for applications require high outputs of power within very tight tolerances, including Traffic lights, Automotive lighting, Power supplies, Motor controllers and High-current circuitry.

0 notes

Text

Water Heater Installation – DIY Or Hire an HVAC Contractor

You are a ballet dancer who recently married a beautiful woman in your troupe. Your new father-in-law, a street-wise homicide detective, is visiting for the very first moment. You guess he secretly harbors reservations about his”Little Miss Splendid” marrying a guy who performs battements tendus and battements frappés all day.

Additionally, just hours prior to your in-laws’ scheduled arrival, your hot water heater suddenly goes kaput. If your young wife solicitously alarms Daddy, gunning the final stretch of a grueling 12-hour excursion, the prospect of having to install a new hot water heater until he could even take a shower sets off a burst. “Why can not that tights-and-slipper-wearing husband of yours do it” You hear him need over the speakerphone. “What’s he? Some sort of [expletive deleted] woos?”

Following the mobile goes dead, your beautiful wife’s teeth are chattering, her knees shaking uncontrollably. Undaunted, you coolly declare that, as a matter of fact, you may replace the hot water heater yourself. After all, who needs an unhinged homicide detective operating round the home, on the brink of a nervous breakdown, just because he can’t take a spa?

What Is It?

A hot water heater is the thirty to fifty-gallon tank tactfully closeted on your kitchen, bath, or some other well-concealed area. Check out Enersure here!

Over time, water heaters wear out. Newer models have extremely sensitive sensors to detect gasoline fumes, which can also occasionally be permanently damaged by Black Flag sprays and foggers you have employed battling invading armies of roaches. In any circumstance, the heater has to be replaced pronto. In other words, if cleanliness and hygiene rank high on your priority list.

When you replace your hot water heater, you’ve got two options. The first would be to take matters in your manly hands and do it yourself. The second option of employing an HVAC contractor is often more prudent for folks unfamiliar with terms such as a wrench, flute (not the instrument), or thermoplastic.

Who Needs It?

Everybody. Hot water heaters heating up the water provided by your cosmetics company, allowing you to do things like revel in sexy, candle-lit bathtubs, clean beautiful bone china, and keep yourself at a steady supply of clean underwear.

HVAC is an abbreviation for Heating, Ventilation, and Ac. HVAC Contractors chiefly specialize in the installation and maintenance of boilers, boilers, and central air conditioners – however, they do warm water heaters. HVAC contractors may also give consultation to customers, about brands and models of equipment to buy. This service is a wee bit strange since it’s a little like searching for a new automobile, beginning with your cranky automobile mechanic.

There are good reasons to employ an HVAC contractor. As an example, in the unlikely event you open your hot water tank’s storage cupboard, and don’t observe a shut-off valve on the gas, an HVAC contractor will have a blowtorch handy to add one. Or, say, you find a cluttered maze of wiring, since you’ve got an old electrical heater. An HVAC contractor will clean this up, ensuring all of the wirings is right, while providing the heater with proper voltage and amperage. Or, ultimately, you locate your hot water heater closet’s an impenetrable jungle of soldered copper, marriages, flex connectors, and thermoplastic – all improvised by your adorable”handyman” over the decades – call an HVAC contractor.

Simply make sure the contractor possesses a clean credit and legal history has been in business for over three decades and fulfills all the state’s licensing requirements.

Benefits

If all the major pipes in your home were completed and conscientiously, disconnecting your old water heater and replacing it with a fresh one is a cakewalk, even if you don’t religiously watch”This Old House.” The only items you’ll need are a spray bottle with soapy water, an adjustable wrench, a screwdriver, and a garden hose.

First, turn off electric power to your gas or electric water heater. If you have a gas water heater, switch off the gas shutoff valve in the source line, too, before disconnecting it. If your gas water heater has a fan unit, then disconnect it. If your water heater’s electric, unplug it. When there’s a cable connection, turn off the power first, then disconnect the cable.

Next, shut off the water source to the water heater. Release the pressure-relief valve. Then, with your garden hose attached to the tank, run it out the window into your dead flower bed, draining the thirty or fifty gallons inside. Following that, disconnect the tank’s water connections.

Enlist both teenaged skateboarders you see, practicing their kickflips in your neighbor’s driveway, to consume this useless hunk of metal off to Home Depot for recycling. While they are picking up the new one, let them slap a few flexible pipe connections on your charge card, too, in case your new water heater’s dimensions are not exactly the same as the older ones.

Once the new tank’s been dutifully lugged home, connect the new collar into the flue. One sobering and cautionary note: proper venting is essential to avoid carbon monoxide poisoning. So put the draft deflector collar above the water heater flue baffle, then attach it to the flue pipe venting outdoors. A careful reading of the manufacturer’s instructions, as far as you might resist, will delightfully light activities like this one.

Today, turn on the water valves. Your new hot water tank is filling up. Check your water connections for leaks. Additionally, assess the gas fittings with the spray bottle full of soapy to see whether there are any gas leaks. If a connection’s loose, and needs trimming, you will see tiny little bubbles. When you’re absolutely sure the connections are leak-proof, light the pilot, or turn on the power source.

Risks

There are not many hot water heaters made with no temperature and pressure-relief valves. Make sure your brand new heater has one. It’s a very important safety device. Without one, your own water heater may actually explode into a great ball of flame.

Finally, be cautious when first placing the water heater’s temperature estimate. Your new father-in-law’s attitude may be magically transformed by your breathtaking home-improvement abilities, but you do not want to end up scalding him to death the minute he steps into the bathtub. http://enersure.ca/rental/water-heater

from Echecs Montreal http://bit.ly/2VX9C0A

0 notes

Text

New Bendable RJ45 Flex Connector from Platinum Tools Eases Network Cable Terminations

Bendable RJ45 Flex Connector is available in shielded and non-shielded versions. Units are rated to electronic safety and security applications such as PoE+ rated, 1GHz, and 10-Gigabit certified for high data traffic. Designed to accommodate multiple category sizes up to 9.0mm with 24-22 AWG conductors, units can drop at 90 degree down or 45 degree up and the patented design offers improved performance for Cat5e/6/6A cabling.

This story is related to the following:

Mounting & Attaching Products

Search for suppliers of: Connectors

from HVAC /fullstory/new-bendable-rj45-flex-connector-from-platinum-tools-eases-network-cable-terminations-40011528

via http://www.rssmix.com/

0 notes

Text

HELUKABELâ�(TM)s M12 and RJ45 Connectors offer transmission rates of up to 10 GBit/s.

HELUKABEL’s M12 and RJ45 Industrial Connectors are designed for static, occasional movement, or continuous-flex applications. Molded M12 connectors are offered in D- and X-coded versions in both male and female and feature metal casing whereas the RJ45 connectors are available in linear or angled version and provide maximum bandwidth of 500 MHz. The units are compliant to UL and CSA standards.

from HVAC /fullstory/helukabel-s-m12-and-rj45-connectors-offer-transmission-rates-of-up-to-10-gbit-s-40010194

via http://www.rssmix.com/

0 notes